Desilter

Working principle and structural features

Working principle: Model CNQ-100×12desilter is mainly composed of charge incoming-stream tube, overflow discharge pipe, cyclone assembly, vibration screen, pedestal and support, etc.

At the time of operation, under the effect of pressure, the drilling fluid containing suspended solids enters the cyclone from the charge incoming-stream tube via the tangential inlet at the cylindrical volute casing part on the upper part of cyclone, it rotates and moves downward, there is density difference between the solid phase and liquid phase in the drilling fluid, in addition, the upper part of cyclone is big and its lower part is small, with the downward movement of drilling liquid, it obtains greater angular velocity, as a result, it obtains greater radial acceleration, greater accelerated downward movement closely against the cone wall is generated, it is discharged from the head piece at the bottom, the liquid phase with low density forms low pressure vortex current at the inlet of cyclone, and the liquid phase with downward rotational flow movement will also generate pressing at the bottom of rotational flow, it moves upward in the inverse direction, it is discharged from the overflow opening and returns to the circulating system.

In addition, the underflow extruded through the cyclone falls onto the vibration screen cloth, the drilling fluid passing through the screen and barite with big grain size return to the circulating system, and the solid phase of harmful object on the screen is removed. (Refer to the following diagram).

Installation and Use

1、 A hanging ring is designed at the top of model CNQ-100×12desilter, which is for use in shipping and installing, there are two φ219 pup joints for commutating and welding flange, elbow or barbed tube, etc.

2、 At the time of installation, according to the circumstance of site, the desilter can be firmly mounted to an appropriate position on No.2 tank.

3、 According to the need, use 6〃 hose or 6〃 steel tube to firmly connect the vent for charge sand pump and the inlet of charge liquid of desilter.

4、 Check the exterior of equipment to be scratched or not with circumstance of no sinkage or not, remove the clamping plate of vibration screen, switch on the power supply for the motor of vibration screen.

5、 Energize to check the rotation direction of motor and the operation circumstance of vibration screen, apply appropriate amount of grease to each movement part, start the charge pump, check the pressure of pressure gauge to be within the scope of operating pressure or not, check each connective part to have phenomenon of leakage or not, in case of any leakage, the screw at the leakage part may be screwed tight. Adjust the underflow nut of the cyclone, so that its underflow is discharged in the umbrella shape.

6、At the time of stopping use, the sand pump shall be firstly closed, the mud in the pump shall be thoroughly discharged in winter, the screen cloth shall be washed clean, switch off the power supply for motor of the vibration screen, and check each part for any abnormality or not.

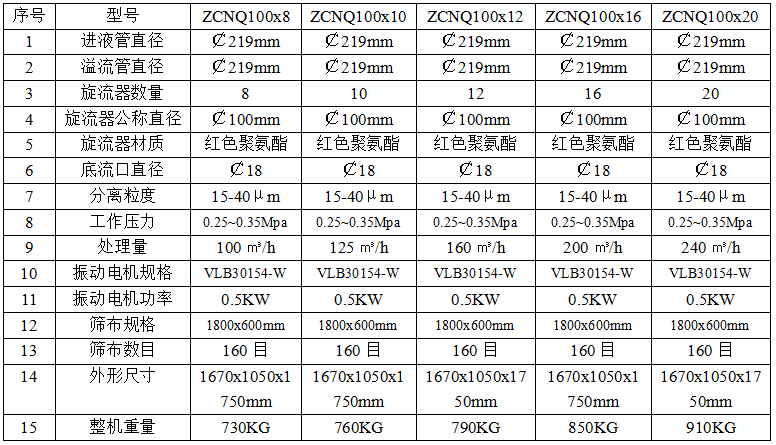

technical parameter

Tel:Whatsapp

Tel:Whatsapp Tel:+86-18303261131

Tel:+86-18303261131 Email:fortunel@fdpetrol.com

Email:fortunel@fdpetrol.com Address:Xinhua Park,Economic Development Zone,Cangzhou City,Hebei Province,China.

Address:Xinhua Park,Economic Development Zone,Cangzhou City,Hebei Province,China.