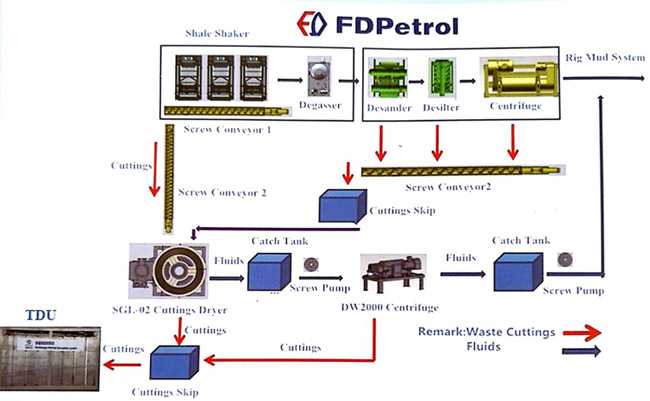

FD Petrol two stages system to treat the OBM drill waste to different discharge standard.

First Stage:Treatment While Drilling (Online Treatment to 5% OOC)

The drill cuttings are collected and treated by mechanical centrifugal separation system,recover most of the base oil,minimize the oil content in waste cuttings(3%-5% OOC cuttings discharged from SGL-02 cuttings dryer,13% OOC cuttings discharged from DW2000 centrifuge),the cuttings are transported to waste management plant.liquid phase return to active mud system.

Second Stage: Thermal Desorption System(Mobile or Stationary Olant to 1% OOC)

Treat the gathered drill waste from stage 1 to less then 1% OOC so as to meet more strict discharge standard,water and oil are relaimed and reused.

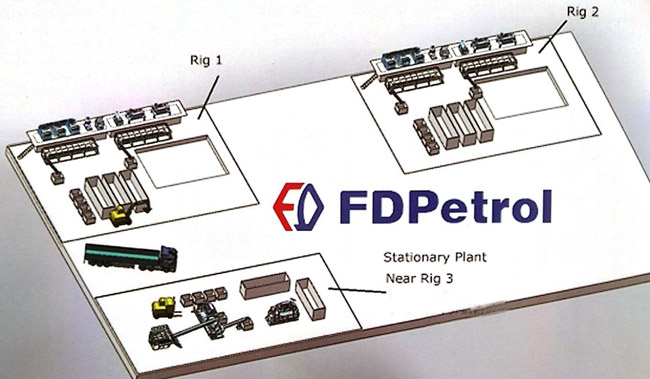

The two stage treatment method can make the system operate in different time,different areas,high efficiency usage for the equipment,operate in low energy consumption mode.

FD Petrol Complete OBM Drilling Waste Management Flow Chart

The Systen Design Basis:

a.The system is designed to serve for 2 or 3 drilling team so that can maximize the usage efficiency,minimize investment and work load.

b.The sytem operate in chopping mode The advantages of FD online treatment is to minimize the drill waste volume from headstream, the waste after treatment is convenient to store and transport,minimize the afterword MTDS treatment time and energy consuming.

No secondary pollution and the reclaimed fluids can reuse again.

Pure mechanical separation technology

The reclaimed fluids can reuse again and no secondary pollution to the environment

Low energy consumption

Total load power is 110kw,55kw is working in chopping mode

Convenient and stable operation system

Compact layout system,convenient to operate and low maintenance rate

Convenient to transport and install

The system can be carried by two 9600mm truck.

Tel:Whatsapp

Tel:Whatsapp Tel:+86-18303261131

Tel:+86-18303261131 Email:fortunel@fdpetrol.com

Email:fortunel@fdpetrol.com Address:Xinhua Park,Economic Development Zone,Cangzhou City,Hebei Province,China.

Address:Xinhua Park,Economic Development Zone,Cangzhou City,Hebei Province,China.